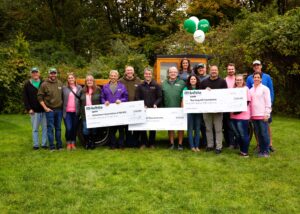

R.H. White has a long history of employee engagement with nonprofit organizations in the communities where its employees live and work. None is more prominent than the relationship between Community Harvest Project and the company.

Community Harvest Project is a non-profit farm that engages volunteers to grow fresh fruits and vegetables to provide to those experiencing hunger. Through its volunteer farming programs, education initiatives, and community partnerships, the organization brings thousands of community members together each year to improve access to healthy foods for individuals and families in need across Worcester County in Massachusetts. Many R.H. White employees have worked the fields on the Community Harvest Project planting, harvesting, weeding, and assisting in many other activities each year.

In one if its latest endeavors, R.H. White volunteered the services of one if its drivers, Mike D’Acri, and a large flatbed tractor-trailer to deliver a new CoolBot refrigeration unit to the organization’s Prospect Hill Orchard location in Harvard, MA.

According to David White, Chairman of the Board at R.H. White, “Like many of our construction projects, there was a lot of pre-planning that went into the transport and delivery of this unit. Mike’s ingenuity in overcoming various obstacles that needed to be addressed is greatly appreciated.”

The cooler was built by the House Carpentry program at Montachusett Regional Vocational Technical School in Fitchburg, MA at no cost. The insulation for the unit was provided by Rmax a Business Unit of SIKA Corporation, with local operations in Canton and Westborough, MA. Without donations of carpentry, goods, and services from the school, Sika, and R.H. White, the price to build and install the cooler would have been cost prohibitive.

According to Wayne McAuliffe, Manager of Volunteer Programs for Community Harvest Project, the CoolBot project was critical to providing a storage cooler in advance of the first full harvest of peaches. “We planted peach trees at the orchard four years ago and they will now produce a significant crop. The key to producing and providing good peaches for our recipients is to ensure that they are picked at peak ripeness and then immediately cooled to slow down their ripening. When done properly you get a top-quality, juicy peach. Peaches that are left at warmer temperatures degrade quickly. Therefore, we needed this cooler in time for our first big harvest. After peach season we will continue to utilize the cooler to store apples for our smaller distribution partners.” McAuliffe explained.

Special thanks go out to Montachusett Regional principal, Tom Browne as well as its Director of Vocational Programs, James Hachey, and Instructor, Shane Brogan, for taking a special interest in building the unit as well as Sika Corporation Senior Vice President, Martin Heiskell, for the RMax insulation donation. Finally, none of this would have been possible without the vision and hard work of Orchard Manager, Susan Conant, Katerina Matjucha, Orchard Assistant, and Wayne McAuliffe who were also instrumental in making this project a reality.

For more information on Community Harvest Project and its volunteer opportunities please visit: www.community-harvest.org/.